- It

- En

Moulding of Plastic Materials, Micro Moulding, In Mold Labelling

-

>

>

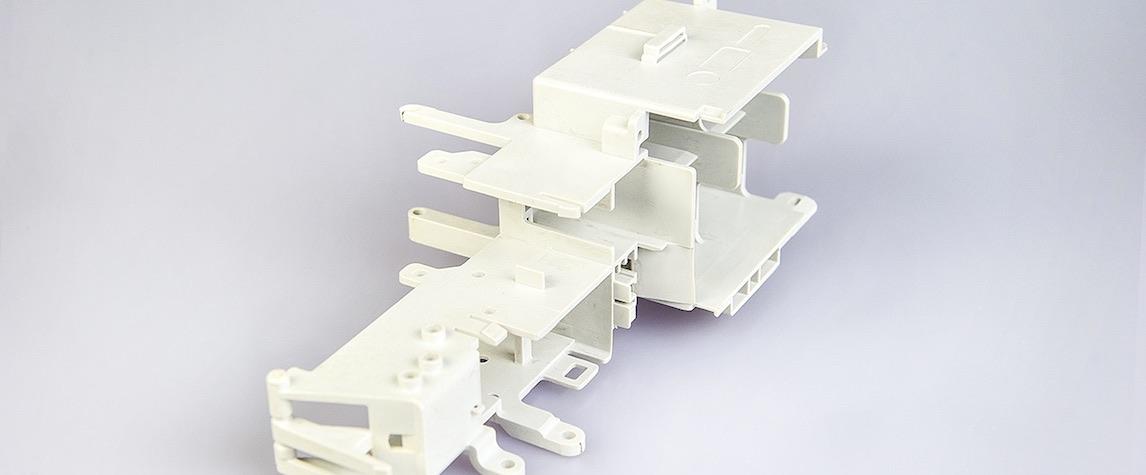

Moulding of Plastic Materials

The moulding department of plastic material operates on a 24-hour basis, with 18 last generation injection moulding machine ENGEL, ARBURG, BABYPLAST...

-

>

>

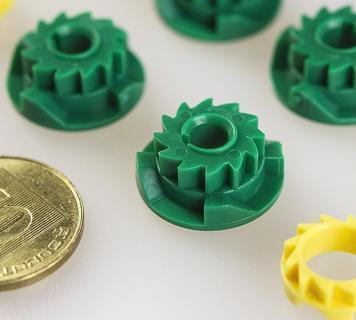

Micro Moulding

MULTI BOX uses BabyPlast moulds for high-precision micro moulding. The moulding department has 3 moulds of 7 tons of this type.

-

>

>

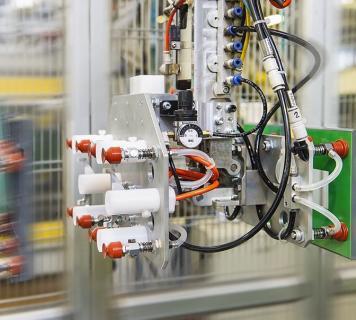

In Mould Labelling (IML) and In Mold Decoration (IMD) Supplier

What is In Mould Labelling (IML)? It is a technology which allows the realization and decoration of articles directly during the injection stage.

-

>

>

Realization of Moulds

MULTI BOX has its own designing unit. Based on the input of our clients, we analyze the feasibility of the project by making use of specific...