- It

- En

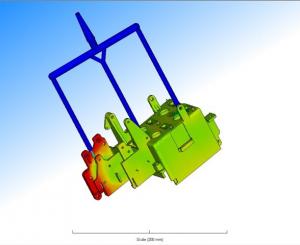

Realization of Moulds

Designing

MULTI BOX has its own designing unit. Based on the input of our clients, we analyze the feasibility of the project by making use of specific simulation software for the analysis of injection and deformation.

MULTI BOX has a Rapid Prototyping machine with technology OBJET ALARIS 3D PRINTER. The timely realization of a prototype supports the stages of development and validation of the project.

Realization of moulds

The employmenmt of a staff trained on a regular basis and of equipment of last generation, allows us to realize moulds of high precision, within the deadlines agreed with our clients.

Our technological assets include:

- CAM systems

- 3/4 axis, high speed CNC millers (30.000 rpm)

- Electrical Discharge Machine - spark erosion

- Electrical Discharge Machine - wire erosion

- Grinders, drills and support tools

- DEA 3D Metrology

Thanks to the presence of human and technological resources which cover the whole production process we can plan the ordinary and extraordinary maintenance of moulds in an efficient manner, in order to support our moulding unit.